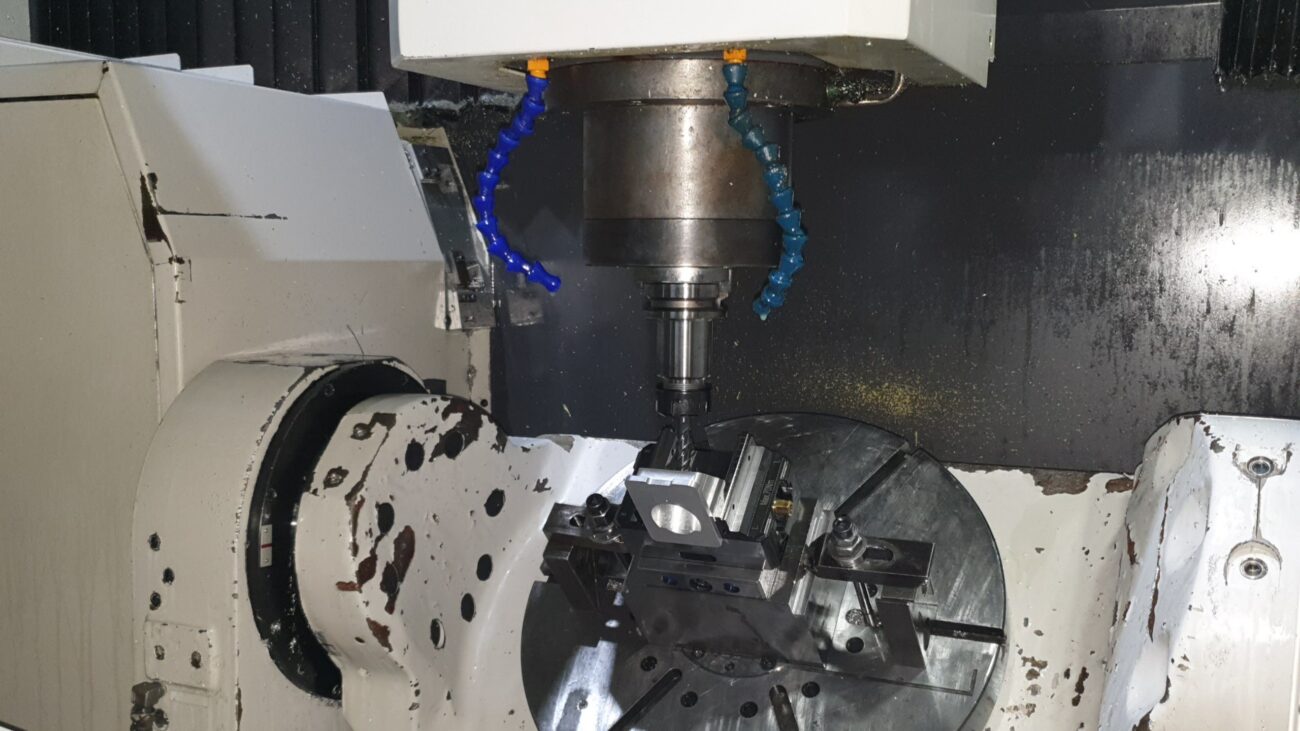

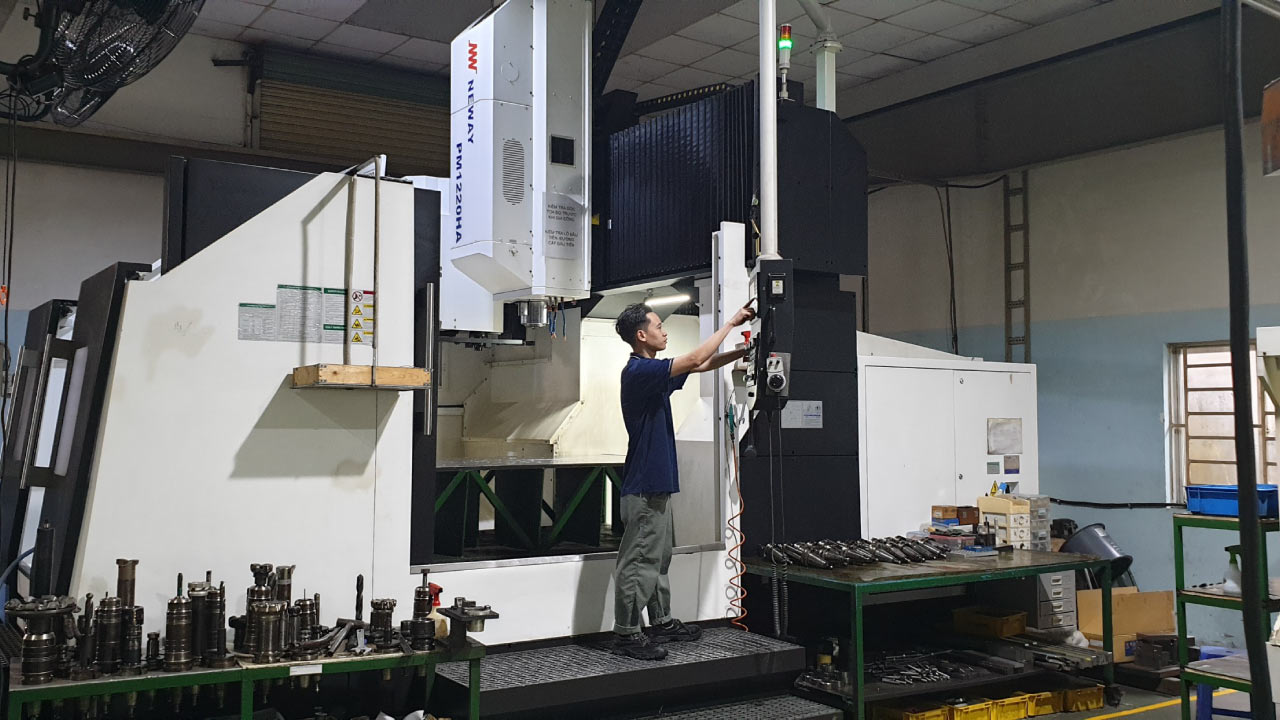

HIGH-PRECISION CNC MACHINING CENTERS

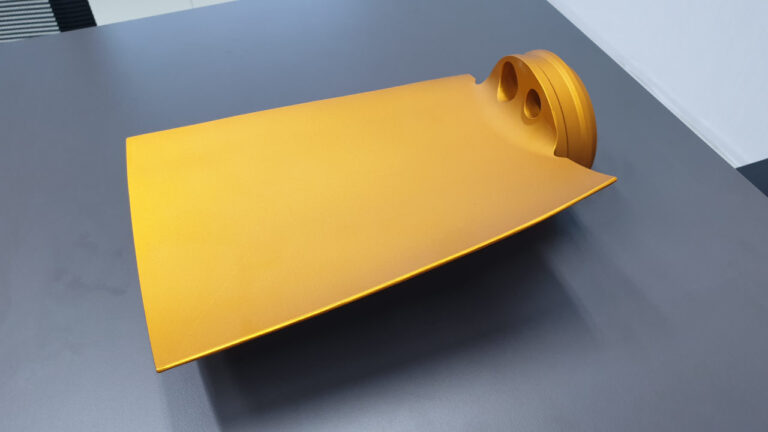

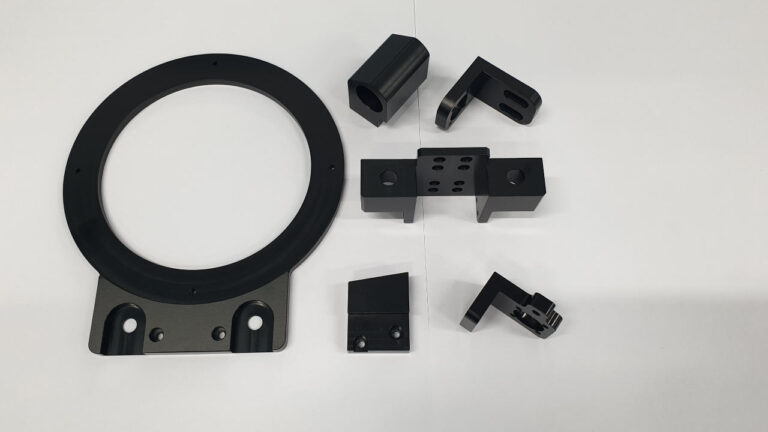

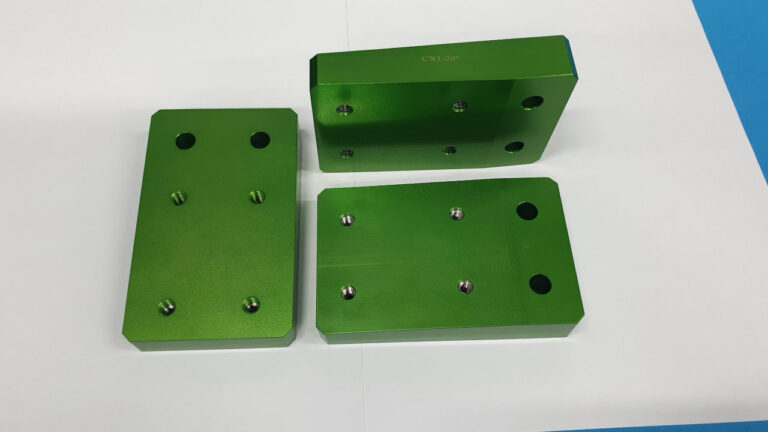

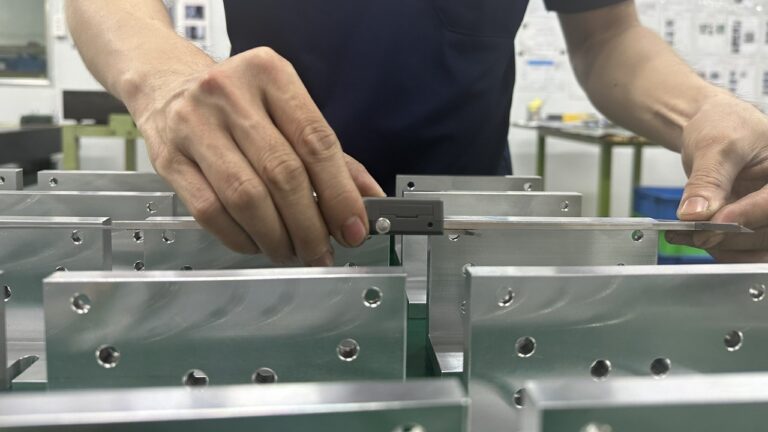

Viet San invests in state-of-the-art CNC machining centers, ranging from 3-axis to 5-axis, enabling the high-precision manufacturing of complex components.

-

3-axis – Precision machining for standard parts.

-

4-axis – Enhanced flexibility, increased productivity, and accuracy.

-

5-axis – Efficiently processes complex geometries, optimizing machining performance.

-

Gantry – Specialized for large and heavy components.

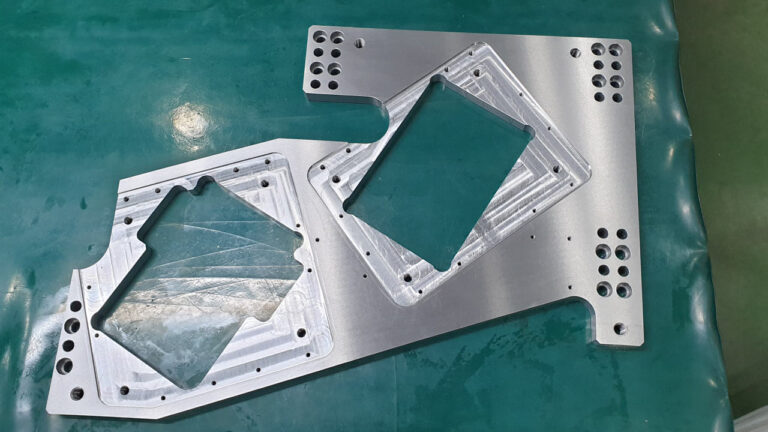

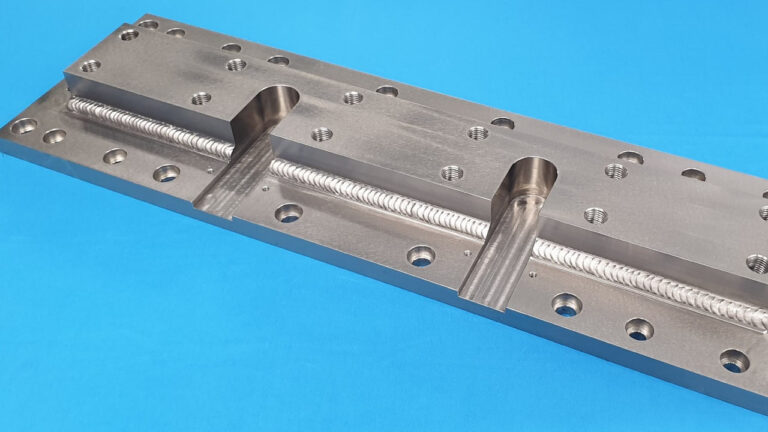

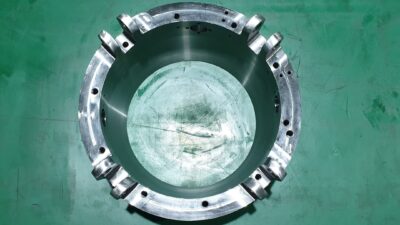

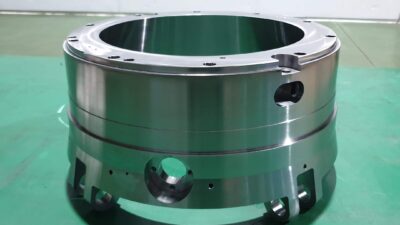

HIGH-PRECISION

CNC TURNING

Our CNC turning system enables high-precision machining of shafts and cylindrical components, meeting the strict standards of our customers.

-

CNC turning – Fast and precise machining, ideal for mass production.

-

Turn-mill machining – Combines turning and milling in a single process, enhancing production efficiency.

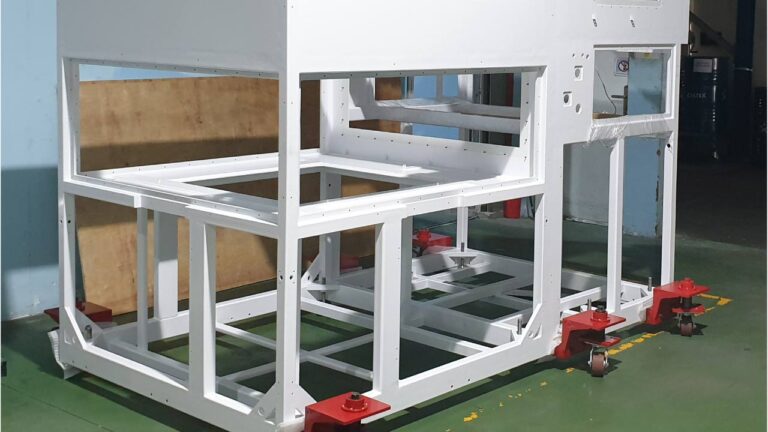

WELDING TECHNOLOGY

Utilizing advanced welding technology, we ensure strong, aesthetically pleasing welds that meet international standards.

-

TIG & MIG welding – Suitable for various materials, from stainless steel to aluminum.

-

Robotic welding – Automated welding for increased productivity and consistent quality.

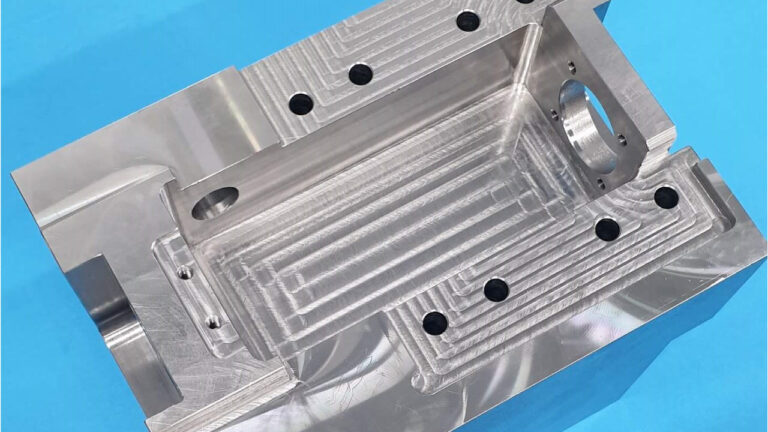

SHEET METAL PROCESSING

Advanced sheet metal processing technology ensures high precision and efficiency in production.

-

CNC Punching – Fast and precise machining of sheet metal components.

-

CNC Laser Cutting – Delivers sharp, high-quality cuts for complex designs.

-

Bending – Forms sheet metal with absolute accuracy.

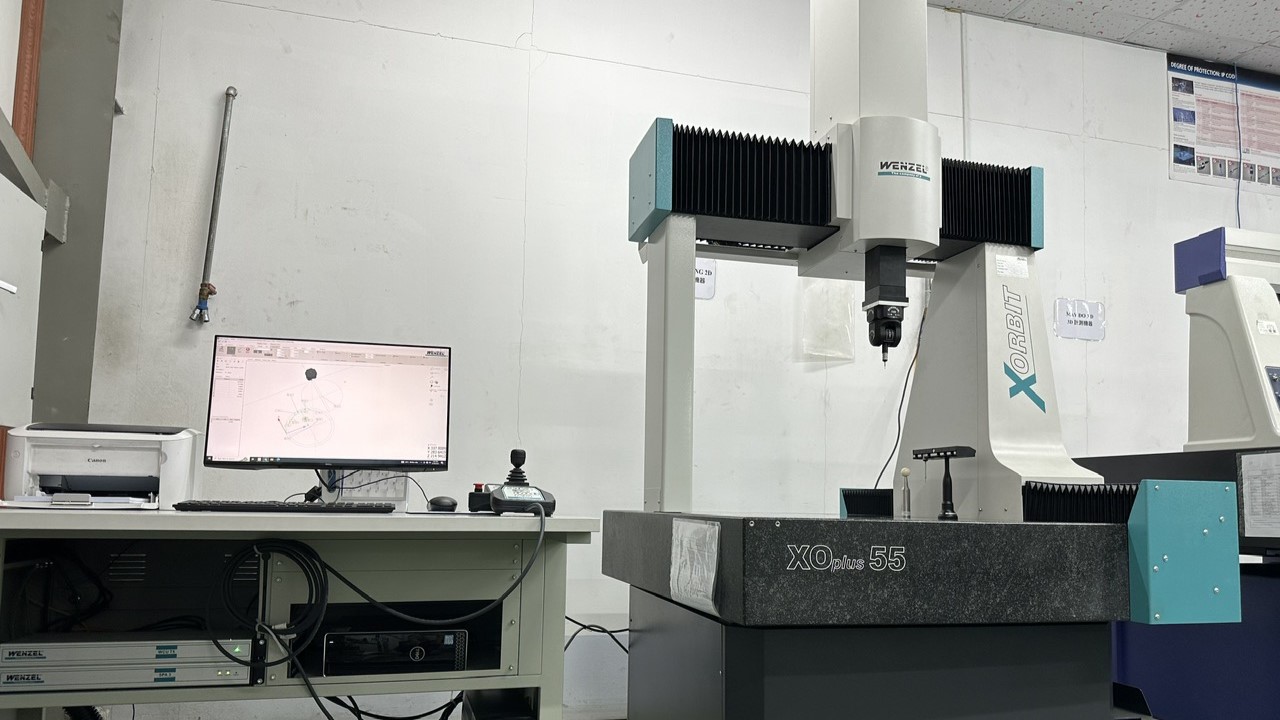

INSPECTION & MEASUREMENT EQUIPMENT

Viet San is committed to the highest quality standards through an advanced inspection and measurement system, ensuring absolute precision for every product.

-

Wenzel 5-Axis CMM – High-precision dimensional inspection, meeting strict industry standards.

-

Faro 3D Measurement System – Flexible inspection, ideal for complex and large-scale components.

Our rigorous quality control system allows Viet San to maintain consistent quality, meeting the technical requirements of both domestic and international customers.